Hydraulic Presss for Metal Sheet Stamping/Stretch Forming

Widely used in electronic and electrical, automobile manufacturing, hardware appliances, food tableware and other fields.

Classification:

Metal Sheet Metal Stamping/stretching Forming Machine/line

Service Phone:

E-mail: TTSales001@taitianyeya.com

Product Description

Features

۞ The racks of this equipment are all specially designed. After the finite element computer analysis, each frame is subjected to annealing and aging treatment after welding to eliminate welding stress, effectively control the amount of deformation, and ensure the strength, rigidity and service life of the rack;

۞ The fuel tank is installed on top, allowing for smoother oil suction. The pipelines are centrally laid out for quick response and sensitive movement. A large number of shock-absorbing and buffering measures are adopted to effectively reduce the probability of leakage. The pipelines mainly adopts German 37°flared welding-free and Walform pipe self-forming ferrule technology, almost no leakage;

۞ This equipment adopts servo pump control system, which has the characteristics of simple system, convenient operation, stable operation, energy saving and environmental protection, etc. With the rapid feeding and discharging system, the running speed and efficiency are infinitely close to that of mechanical punching machines, reaching the highest level of similar equipment in China;

۞ This equipment adopts German Siemens PLC programmable controller and American MTS or German Balluff displacement sensor, which can be well connected with the surrounding equipment signals and wiring. The human-machine interface adopts Chinese/English color touch screen and strong electric control cabinet. / Weak current separation and wiring are all in accordance with CE requirements. It has the characteristics of being in line with international standards, strong identification, easy to read and write, and simple to operate.

Applications

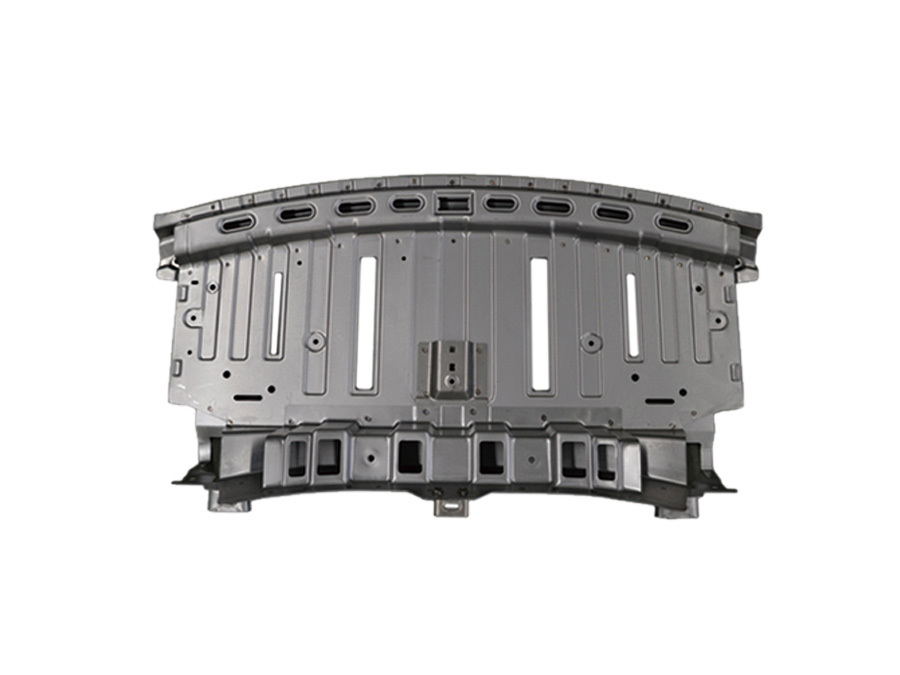

This equipment is specially used for various metal sheet metal separation and forming processes, including cutting, blanking, punching, edge trimming, bending, twisting, undulating, bulging, stretching and other processes. Widely used in electronic and electrical, automobile manufacturing, hardware appliances, food tableware and other fields.

Options

Quick die change system (clamp/die lifter/die shift arm/die change trolley, etc.), lower table removal, four-corner shock absorber, industrial oil cooler/condensate circulation system, translation machine/robot, material separation Tensioners, waste collection systems and more.

keyword: Hydraulic Presss for Metal Sheet Stamping/Stretch Forming

Previous Page:

: Next Page

Next Page

Online Message

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!